At Wolf Components, we’re committed to staying ahead in delivering both manufacturing efficiency and innovation.

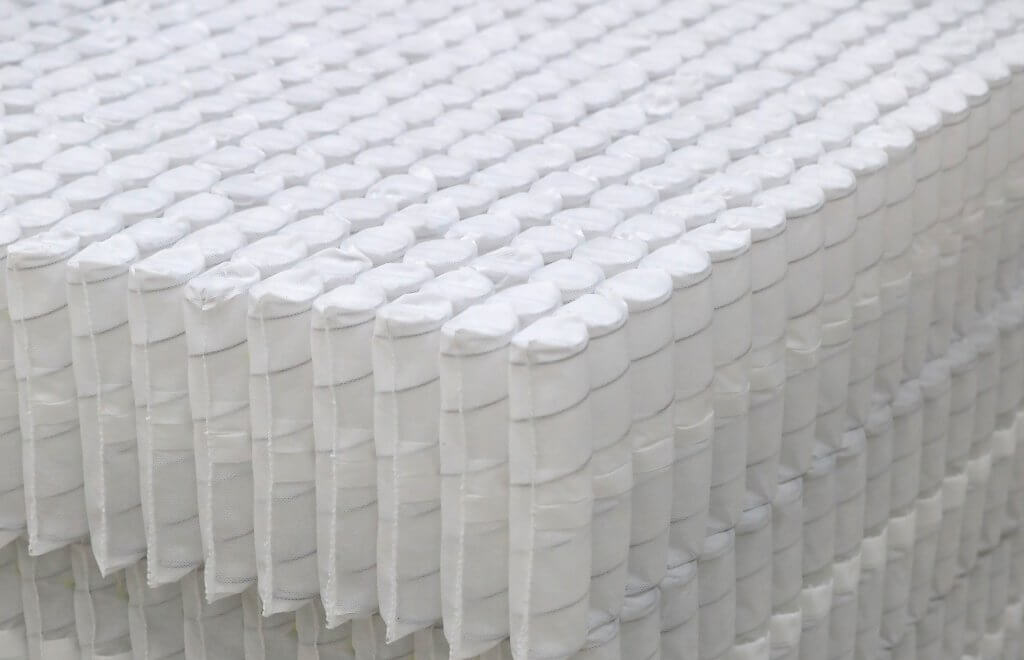

Last year we elevated our production capacity for pocket spring units with the acquisition of a cutting-edge Lian Rou 180 coil-a-minute machine, which has delivered fantastic quality and productivity.

We’re now delighted to announce our continued investment in production technology with the acquisition of a second machine. This move ensures our manufacturing processes remain agile and competitive, keeping us at the forefront of industry standards.

As a business, innovation and efficiency are at the core of everything we do, and this latest investment not only enhances our ‘just in time’ service capability but also our responsiveness as a truly independent local manufacturer.